Partner

Together we are strong EN

Sustainable process for recovering critical materials from all types of lithium-ion batteries.

Groundbreaking recycling technology

Over 90% recovery of all battery materials

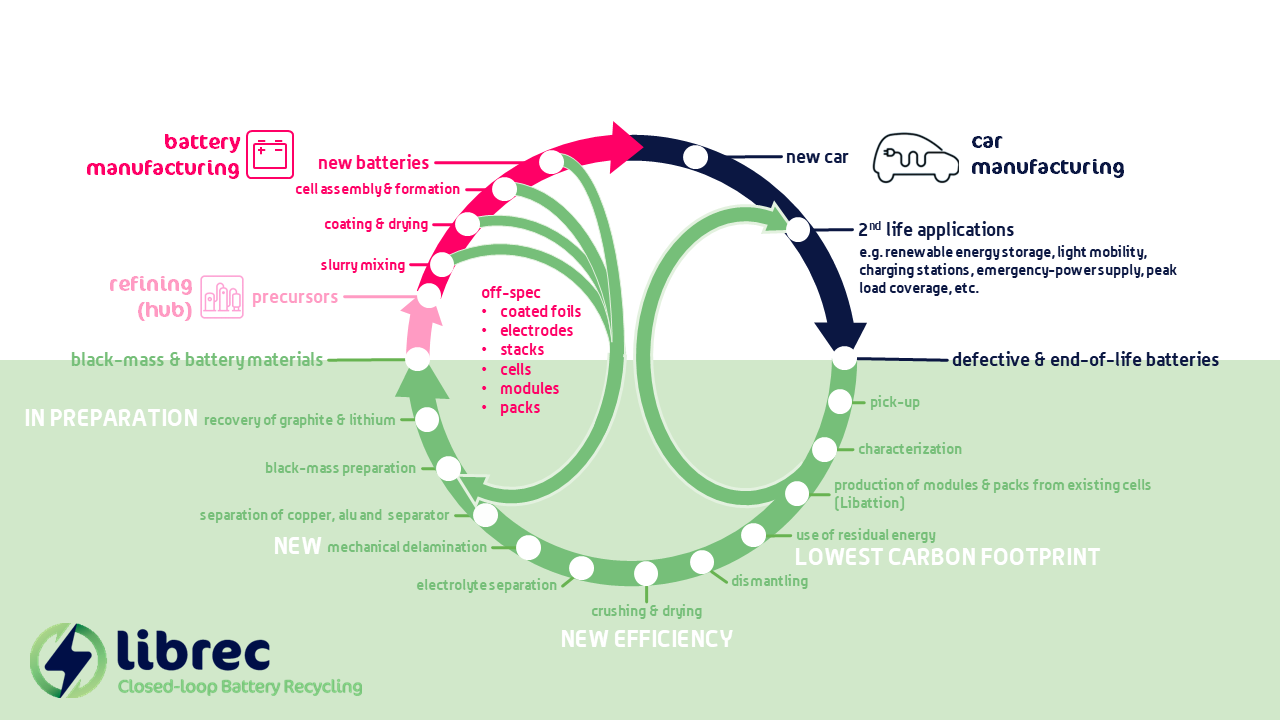

Through its more elaborate approach involving more steps than conventional processes, Librec is able to recover every single one of a battery’s components. In addition to cobalt, nickel, lithium, manganese, copper, aluminium, steel, electronics and the electrolyte, the Librec process also recovers graphite – which makes up 10 to 20% of a battery’s weight – in an energy-efficient manner, without the use of any chemicals.

Groundbreaking recycling technology

Over 90% recovery of all battery materials

Through its more elaborate approach involving more steps than conventional processes, Librec is able to recover every single one of a battery’s components. In addition to cobalt, nickel, lithium, manganese, copper, aluminium, steel, electronics and the electrolyte, the Librec process also recovers graphite – which makes up 10 to 20% of a battery’s weight – in an energy-efficient manner, without the use of any chemicals.

Customer benefits through innovative technology

We achieve the highest recovery rates with the smallest CO2 footprint

Using our own innovative process technology, we recover the residual energy and all materials from the batteries. In doing so, we don't burn or melt anything down. All recyclable materials are fed back into the loop to produce new batteries.

Separate crushing, drying, fractionation and preparation processes enable us to recycle all kinds of production materials with maximum recovery right from the coating stage, ensuring these are available for you to use again as base materials within a very short space of time.

We achieve a new level of efficiency and effectiveness in recycling electrolytes by permanently and innovatively reviewing drying progress (adaptive drying). As a result, we are also able to extract the absolute maximum out of all downstream fractionation and recycling processes, and fully close the loop for all battery materials – with zero loss or contamination.

With our pioneering technology designed to remove valuable active materials (cobalt, nickel, lithium, manganese, graphite, etc.), we achieve unprecedented selectivity and sparkling clean separated materials.

The conducting salt responsible for transporting ions in the battery, usually LiPF6, is complex to produce and is very expensive.

Modern drive-battery systems are also 10 to 20% graphite. Graphite is a naturally occurring carbon compound sourced by mining. Producing it synthetically is very energy-intensive.

Neither substance is recovered through conventional recycling processes. Librec has developed ways to recover these recyclables, and will be demonstrating these on an industrial scale in Switzerland for the first time.

With full, smart discharge, we recover all energy from the batteries and are able to use it to cover as much as a third of our process energy. Together with our own solar power, we ultimately meet more than half of our energy needs this way.

Our state-of-the-art process technology does not require any chemicals whatsoever, keeps resources in the loop and does not produce any emissions (zero emissions).

With our decentralised network for collection and recycling, which is currently being set up throughout Europe, we are able to greatly reduce the generally necessary transportation routes and risks compared to primary mining or the central collection-and-return approach.

Partner

Together we are strong EN

Sustainable process for recovering critical materials from all types of lithium-ion batteries.